This week my friend and fellow forum member, Greg, and I attended another Armorer Course in Ashburn and I thought that many of you would enjoy a post covering the history and evolution of the weapon along with a few photos from that course.

The HK416, which was originally designated as the HKM4 until Colt filed a law suit, was born out of the success of HK's product improvement program on England's SA80 and a desire from some "special customers" within USSOCOM who were looking for a reliable M4 style CQB carbine in around the 10" barrel length. These customers, because of the high volume of shooting done prior to and during each deployment, also placed longer service life on major parts as a primary concern.

With HK's success in utilizing the short stroke gas piston in the G36 family of rifles and the knowledge that in short barrel format, the piston operating system is superior to the direct impengment system, they set about modifying Colt M4s. These grew into the first few prototypes, which were then given to the special customers and tested here in the US and then overseas in combat operations. The result was an overwhelming success and has brought us to where we are now, the fifth version of the HK416.

![]()

All HK416s have cold hammer forged 1/7 twist barrels, to ensure better stabilaztion of the longer and heavier projectiles of the 62 grain 5.56mm ammuntion, now common in NATO countries. In the first four variants, the barrel lengths were offered in 10.4", 14.5", 16.5" and 20"

During this course, we had the opportunity to work on many different variants. Most were 10.4" and 14.5" A1 variants, but as you will see later, the list continued on. So, to eliminate any confusion, here are the different variants and how they are most easily distinguished:

-HK416 (no firing pin spring or firing pin safety)

-HK416A1 (firing pin spring and firing pin safety introduced, only left side receiver recess for charging handle)

-HK416A2 (Over The Beach (OTB) barrels)

-HK416A3 (otherwise known as the Norweigan variant, captive cotter pin on bolt carrier to prevent its loss in the field, safety engagement regardless of the hammer position, protective bridge over the disconnector and a unique to that country's weapon gas regulator and taller flip up sights for use with their top mounted laser designator)

-HK416A4 (not covered)

-HK416A5 (the pinnacle, covered later in this post)

Several other unique features exist with the HK416. First, HK has been able to cold hammer forge the extractors as well. This procedure has resulted in an almost zero failure rate. The Director of Trainining mentioned that he had never seen one break.

Because the short stroke gas piston puts much greater pressure on bolt assembly group and recoil assembly group, a heavy buffer and action spring is required. That buffer is also tungsten filled, a technique used on all HK automatic rifles, in order to prevent "bolt rebound" our out of battery fire.

The buffer tube also has two adjustable pins which allow the user to eliminate "slop" in the buttstock by tightening those screws.

Several different sight options are available for the rifles. Initially HK offered three different versions of the famous diopter sights. One version was for the 10.4", another for both the 14.5" and 16.5" and the last for the 20". These can be identified and distinguished from eachother by the number of yellow dots below the number 2 on each diopter cylinder; one, two or three dots, corresponding with the barrel lengths just mentioned.

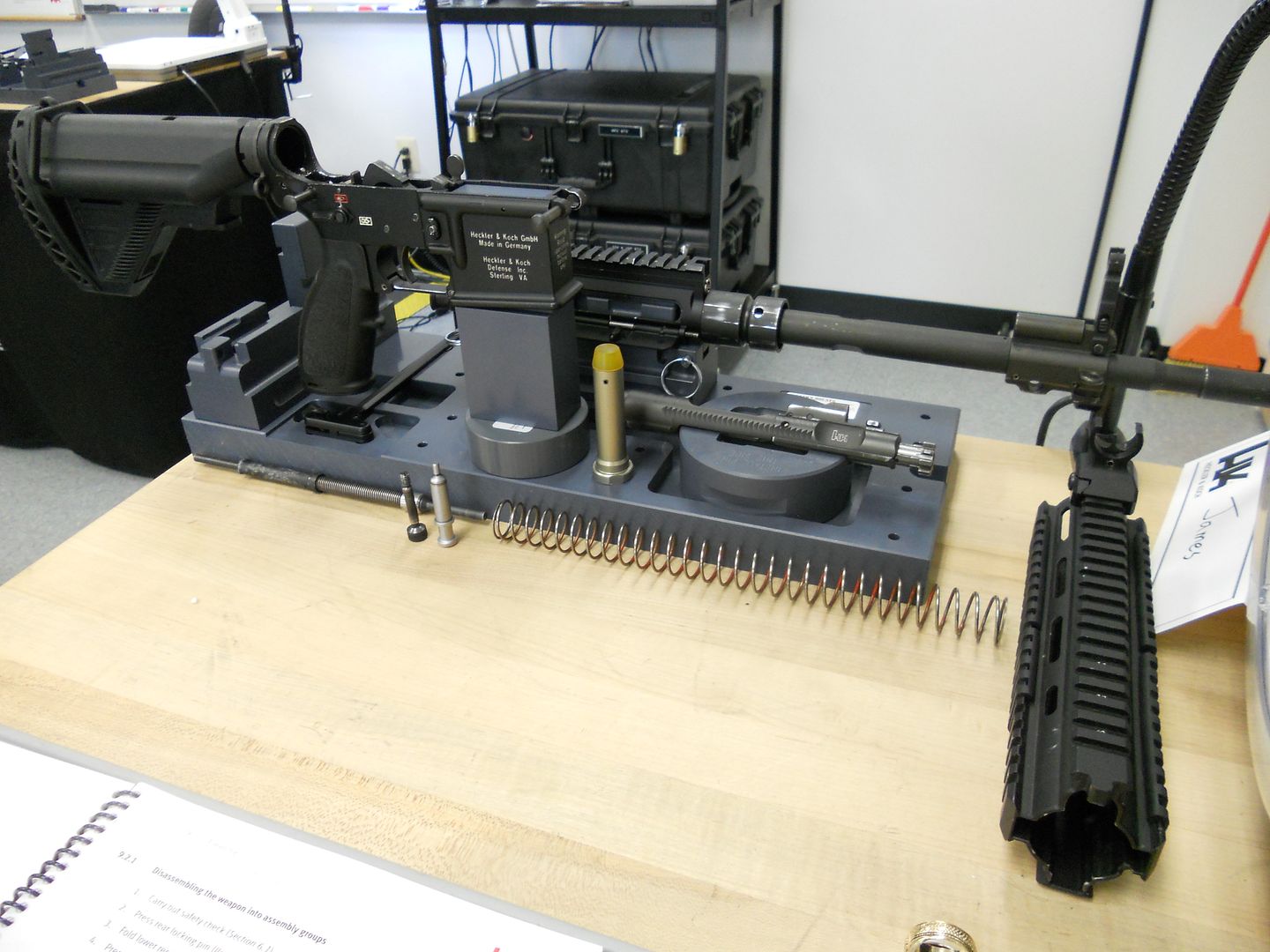

Tooling was also excellent as you would expect from HK. Most notable was the disassembly Multi-tool, which when used in conjunction with a torque wrench, was capable of removing the flash hider, barrel and castle nut. A special mount for removing the buffer tube made quick work of that task and a slick bench set made general disassembly and reassembly very easy where your hands were otherwise occupied holding a hammer and punch. Another special tool is required to remove and replace the ejector.

![]()

![]()

![]()

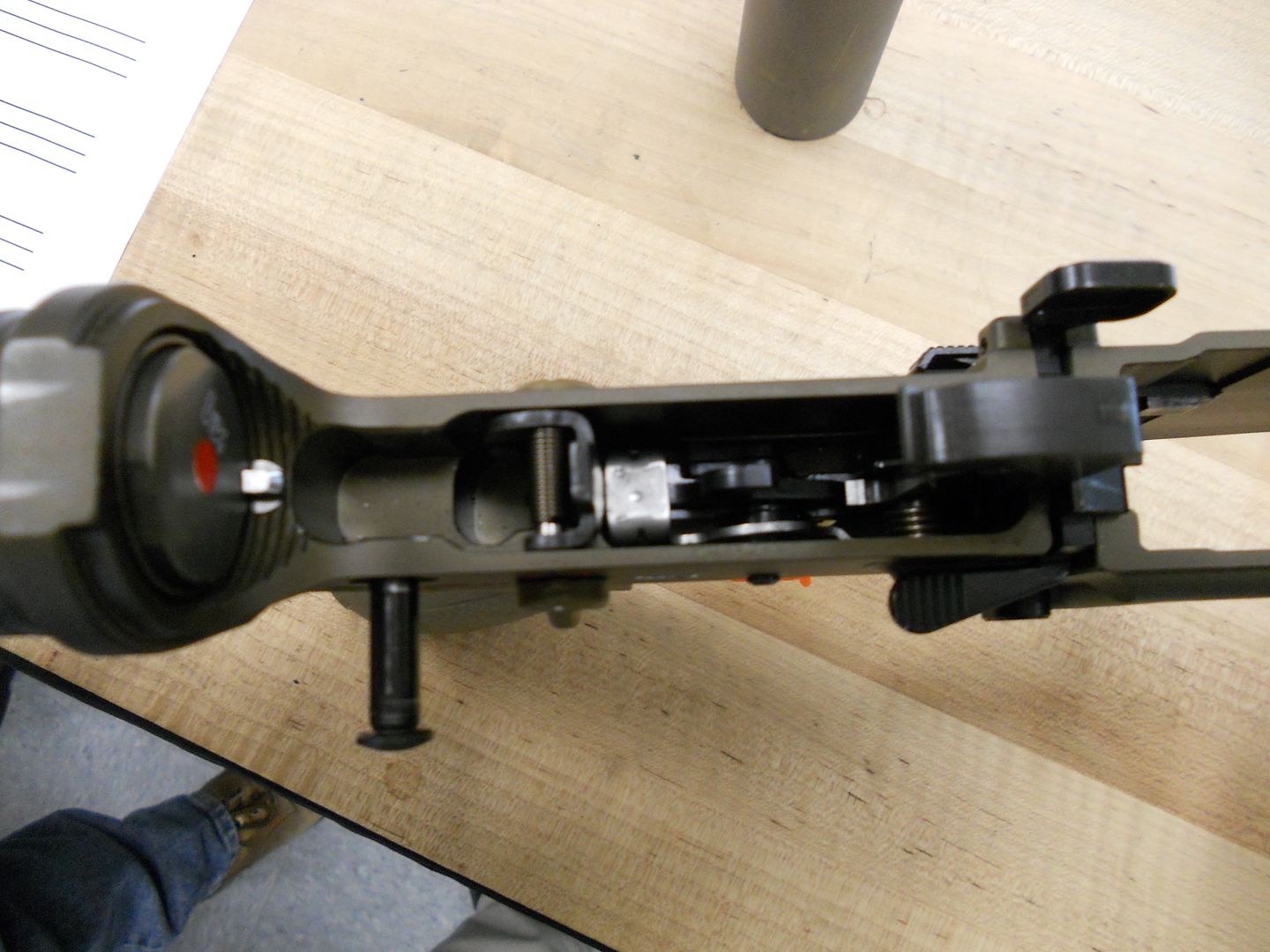

I also find the training cutaway weapons to be incredibly effective at illustrating the 8 step cycle of operation. The HK416 here did not disappoint.

![]()

One of the high points for me was when for one portion of the training, I was provided with one of the three prototypes used in the development of the Marine Corps M27 project. Internally, I could see wear marks in the top of the upper receiver from where the cam on the bolt had been making contact. This was corrected by incorporating a larger recess in the receiver to allow unimpended movement of the cam. Also, at the request of the Marine Corps to optimize performance across all environments where the weapon could be used, the gas block was modified to increase the size of the gas port slightly, thus reducing the overall cyclic rate.

![]()

Also visible in this comparison photo between a standard HK416 bolt carrier and a M27 prototype bolt carrier, you will see the captive cotter pin on the bottom.

![]()

Another point of interest was the discussion surrounding the OTB features. Many people think that this just applies to the barrel, where some additional port exists to aid in in draining water quickly from the barrel in order to allow an operator to fire immediately upon surfacing or to prevent catastrophic failure of he weapon if it were accidentally discharged underwater.

In reality, the OTB features are three part and there is no special port in the barrel. Instead, there exists two drain points. One is a series of ports at the rear of the buffer tube to allow water to drain from the area occupied by buffer and action spring.

![]()

Second, a relief vent at the bottom of the bolt carrier allows water to drain from the bolt assembly.

![]()

And third, in order to reinforce the path of least resistance to a water filled barrel, where the extractor could be blown out of the receiver, a special stud inside the extension puts pressure on the extractor when the bolt is in battery. This, combined with a reduced chamfer in the chamber of these OTB barrels provides the support needed for this capability.

Seen below is a view of an OTB barrel from the chamber. If you look closely (here in comparison to a standard barrel mounted in the receiver to the right for contrast) you can see the stud which is positioned just above where the extractor sits when the bolt is in battery.

![]()

Of course, this capability comes at a cost. The OTB barrels do not feed as reliably when utilizing fragible and soft point ammo, especially during the last two rounds in a magazine when the magazine spring pressure is the weakest.

While working on the lower receivers, we practiced disassembly and reassembly of the standard triggers, as well as that of the "Two Stage" trigger. Similar to those offered by other trigger specialists, it effectively reduces the trigger pull down to around 3.5 pounds (very similar to the MR trigger), but also incorporates a set screw to reduce the length of pull and reset. These kits also include a modified two-piece hammer and can be "dropped in" to either the HK416 or MR556A1.

![]()

And here along with a standard HK416 trigger. With the protective bridge and disconnector removed from its complete set shown above, you can see more clearly the difference in the trigger rebound springs between the two.

![]()

And here a side by side comparison between a MR556A1 on the left and and a HK416A1 on the right. Notice the lack of the protective bridge on the HK416A1.

![]()

Before we wrapped up our training, we got to spend some time going over one of the HK416A5 demo rifles. Looking at it, I found it hard to imagine being able to advance the M4 platform much further. From the front, the biggest noticeable difference is the addition of the adjustable gas regulator. For those who want to utilize a suppressor, this is a huge benefit. When the selector is set to "S", the regulator exposes a relief port on the side of the gas block, which vents off extra gas, not needed to actuate the operating rod, to the right side of the rifle, user the free floating rail system. Because of the addition of this adjustable gas regulator, on the A5 variant, the shortest barrel length has been extended from 10.4" to 11".

The gas block on the A5 is also different. No longer is removable from the barrel. In order to provide the most complete seal, the gas block is heat shrunk to the barrel. And that barrel is now a lighter profile than the previous variants in order to save weight.

![]()

Moving back, the next update is a more aggressive barrel nut and an updated bushing for the operating rod's interface with the upper receiver. In previous variants, that bushing screwed into position. On the A5, the bushing is inserted in and held in place with a retaining pin. This modification increases the life span of the bushing and prevents creep.

![]()

Obviously, the external ambidextrous magazine release and bolt catch are seen on the outside of the receiver.

![]()

Internally, the "bridge" over the disconnector and ability to put the weapon on safe regardless of the position of the hammer are carry overs from the A4 and MR variants. The hammer is also the newer two-piece hammer with rebound spring also similar to that of the A4 and MR variants. Seen below, the protective brige is clearly present.

![]()

The grip, may look the same as previous ones, but internally, the battery storage is removed and in its place is a cavity for holding a new Multi-tool, which holds all of the special tools you need. We were all surprised that the Multi-tool had not been "liberated" yet. Very cool item.

![]()

In an effort to tighten the interface between the upper and lower receiver, but without incorporating the MR unique take down pins, the A5 variant utilizes a small flat spring on the inside of the rear take down point which interfaces with a standard-type take down pin.

![]()

Up on top, the A5 now incorporates a full length picatinny rail. No longer is there the gapped space between the front of the upper receiver and the free floating rail system. Additionally, the rear of the rail is now extended one more position.

![]()

Noticeable as well is the integrated, flip up front sight and the rear sight from the Norwegian project. There is work afoot at HKO to provide a more slimline rail soon too.

![]()

Finally, a more narrow, low profile buttstock and flat Buttpad round out the weapon.

Along with the A5, we had a brief period of instruction in the interface of the HK416 series with the HK grenade launchers. Seen here, we simply slid off the telescoping stock for the grenade launcher and then slid the launcher onto the free floating rail system. Look closely at the HK53 flash hider and the buttstock and you might be able to tell what customer this demo gun was put together for. Also, the polymer mag in this rifle is one of the early prototypes that I remember seeing for the first time a couple of years ago.

![]()

When we moved on to the Gray Room Tour, I chose to focus my attention on the three early HKM4 variants. Clearly noticeable in the photos is how large the gas blocks were on these early guns.

![]()

![]()

![]()

Many of you, with MR556A1s and the few of you with HK416s, may ask what spare parts should I keep on hand? Well, of course I asked and the answer was the disconnector and it's retaining pin, firing pin and firing pin spring and the gas piston rings (as these wear, you'll begin to expereince underfunction in the form of failure to extract and eject). But before you rush out and stock up, I'll tell you that upon arriving back at work, I called over to our Armory to check with our Armory Chief on what parts have failed and needed replacement on our M27 IARs and he responeded with...wait for it...NOTHING. Sure that doesn't mean that you're never going to have a part fail, but it sure is impressive.

As for maintenance, the recommendation was FIRECLean and Scotch Bright 7447 for the gas piston. That combination has been very effective, especially when shooting suppressed.

![]()

And while I'm at it, here are a few other interesting items of discussion from our trip to Ashburn:

-The PSG1 has been officially discontinued/MSG1 still available

-France is replacing all of their FAMAS rifles and the HK416 will be entered in the program.

-VP9 Armorer Course coming soon!

The HK416, which was originally designated as the HKM4 until Colt filed a law suit, was born out of the success of HK's product improvement program on England's SA80 and a desire from some "special customers" within USSOCOM who were looking for a reliable M4 style CQB carbine in around the 10" barrel length. These customers, because of the high volume of shooting done prior to and during each deployment, also placed longer service life on major parts as a primary concern.

With HK's success in utilizing the short stroke gas piston in the G36 family of rifles and the knowledge that in short barrel format, the piston operating system is superior to the direct impengment system, they set about modifying Colt M4s. These grew into the first few prototypes, which were then given to the special customers and tested here in the US and then overseas in combat operations. The result was an overwhelming success and has brought us to where we are now, the fifth version of the HK416.

All HK416s have cold hammer forged 1/7 twist barrels, to ensure better stabilaztion of the longer and heavier projectiles of the 62 grain 5.56mm ammuntion, now common in NATO countries. In the first four variants, the barrel lengths were offered in 10.4", 14.5", 16.5" and 20"

During this course, we had the opportunity to work on many different variants. Most were 10.4" and 14.5" A1 variants, but as you will see later, the list continued on. So, to eliminate any confusion, here are the different variants and how they are most easily distinguished:

-HK416 (no firing pin spring or firing pin safety)

-HK416A1 (firing pin spring and firing pin safety introduced, only left side receiver recess for charging handle)

-HK416A2 (Over The Beach (OTB) barrels)

-HK416A3 (otherwise known as the Norweigan variant, captive cotter pin on bolt carrier to prevent its loss in the field, safety engagement regardless of the hammer position, protective bridge over the disconnector and a unique to that country's weapon gas regulator and taller flip up sights for use with their top mounted laser designator)

-HK416A4 (not covered)

-HK416A5 (the pinnacle, covered later in this post)

Several other unique features exist with the HK416. First, HK has been able to cold hammer forge the extractors as well. This procedure has resulted in an almost zero failure rate. The Director of Trainining mentioned that he had never seen one break.

Because the short stroke gas piston puts much greater pressure on bolt assembly group and recoil assembly group, a heavy buffer and action spring is required. That buffer is also tungsten filled, a technique used on all HK automatic rifles, in order to prevent "bolt rebound" our out of battery fire.

The buffer tube also has two adjustable pins which allow the user to eliminate "slop" in the buttstock by tightening those screws.

Several different sight options are available for the rifles. Initially HK offered three different versions of the famous diopter sights. One version was for the 10.4", another for both the 14.5" and 16.5" and the last for the 20". These can be identified and distinguished from eachother by the number of yellow dots below the number 2 on each diopter cylinder; one, two or three dots, corresponding with the barrel lengths just mentioned.

Tooling was also excellent as you would expect from HK. Most notable was the disassembly Multi-tool, which when used in conjunction with a torque wrench, was capable of removing the flash hider, barrel and castle nut. A special mount for removing the buffer tube made quick work of that task and a slick bench set made general disassembly and reassembly very easy where your hands were otherwise occupied holding a hammer and punch. Another special tool is required to remove and replace the ejector.

I also find the training cutaway weapons to be incredibly effective at illustrating the 8 step cycle of operation. The HK416 here did not disappoint.

One of the high points for me was when for one portion of the training, I was provided with one of the three prototypes used in the development of the Marine Corps M27 project. Internally, I could see wear marks in the top of the upper receiver from where the cam on the bolt had been making contact. This was corrected by incorporating a larger recess in the receiver to allow unimpended movement of the cam. Also, at the request of the Marine Corps to optimize performance across all environments where the weapon could be used, the gas block was modified to increase the size of the gas port slightly, thus reducing the overall cyclic rate.

Also visible in this comparison photo between a standard HK416 bolt carrier and a M27 prototype bolt carrier, you will see the captive cotter pin on the bottom.

Another point of interest was the discussion surrounding the OTB features. Many people think that this just applies to the barrel, where some additional port exists to aid in in draining water quickly from the barrel in order to allow an operator to fire immediately upon surfacing or to prevent catastrophic failure of he weapon if it were accidentally discharged underwater.

In reality, the OTB features are three part and there is no special port in the barrel. Instead, there exists two drain points. One is a series of ports at the rear of the buffer tube to allow water to drain from the area occupied by buffer and action spring.

Second, a relief vent at the bottom of the bolt carrier allows water to drain from the bolt assembly.

And third, in order to reinforce the path of least resistance to a water filled barrel, where the extractor could be blown out of the receiver, a special stud inside the extension puts pressure on the extractor when the bolt is in battery. This, combined with a reduced chamfer in the chamber of these OTB barrels provides the support needed for this capability.

Seen below is a view of an OTB barrel from the chamber. If you look closely (here in comparison to a standard barrel mounted in the receiver to the right for contrast) you can see the stud which is positioned just above where the extractor sits when the bolt is in battery.

Of course, this capability comes at a cost. The OTB barrels do not feed as reliably when utilizing fragible and soft point ammo, especially during the last two rounds in a magazine when the magazine spring pressure is the weakest.

While working on the lower receivers, we practiced disassembly and reassembly of the standard triggers, as well as that of the "Two Stage" trigger. Similar to those offered by other trigger specialists, it effectively reduces the trigger pull down to around 3.5 pounds (very similar to the MR trigger), but also incorporates a set screw to reduce the length of pull and reset. These kits also include a modified two-piece hammer and can be "dropped in" to either the HK416 or MR556A1.

And here along with a standard HK416 trigger. With the protective bridge and disconnector removed from its complete set shown above, you can see more clearly the difference in the trigger rebound springs between the two.

And here a side by side comparison between a MR556A1 on the left and and a HK416A1 on the right. Notice the lack of the protective bridge on the HK416A1.

Before we wrapped up our training, we got to spend some time going over one of the HK416A5 demo rifles. Looking at it, I found it hard to imagine being able to advance the M4 platform much further. From the front, the biggest noticeable difference is the addition of the adjustable gas regulator. For those who want to utilize a suppressor, this is a huge benefit. When the selector is set to "S", the regulator exposes a relief port on the side of the gas block, which vents off extra gas, not needed to actuate the operating rod, to the right side of the rifle, user the free floating rail system. Because of the addition of this adjustable gas regulator, on the A5 variant, the shortest barrel length has been extended from 10.4" to 11".

The gas block on the A5 is also different. No longer is removable from the barrel. In order to provide the most complete seal, the gas block is heat shrunk to the barrel. And that barrel is now a lighter profile than the previous variants in order to save weight.

Moving back, the next update is a more aggressive barrel nut and an updated bushing for the operating rod's interface with the upper receiver. In previous variants, that bushing screwed into position. On the A5, the bushing is inserted in and held in place with a retaining pin. This modification increases the life span of the bushing and prevents creep.

Obviously, the external ambidextrous magazine release and bolt catch are seen on the outside of the receiver.

Internally, the "bridge" over the disconnector and ability to put the weapon on safe regardless of the position of the hammer are carry overs from the A4 and MR variants. The hammer is also the newer two-piece hammer with rebound spring also similar to that of the A4 and MR variants. Seen below, the protective brige is clearly present.

The grip, may look the same as previous ones, but internally, the battery storage is removed and in its place is a cavity for holding a new Multi-tool, which holds all of the special tools you need. We were all surprised that the Multi-tool had not been "liberated" yet. Very cool item.

In an effort to tighten the interface between the upper and lower receiver, but without incorporating the MR unique take down pins, the A5 variant utilizes a small flat spring on the inside of the rear take down point which interfaces with a standard-type take down pin.

Up on top, the A5 now incorporates a full length picatinny rail. No longer is there the gapped space between the front of the upper receiver and the free floating rail system. Additionally, the rear of the rail is now extended one more position.

Noticeable as well is the integrated, flip up front sight and the rear sight from the Norwegian project. There is work afoot at HKO to provide a more slimline rail soon too.

Finally, a more narrow, low profile buttstock and flat Buttpad round out the weapon.

Along with the A5, we had a brief period of instruction in the interface of the HK416 series with the HK grenade launchers. Seen here, we simply slid off the telescoping stock for the grenade launcher and then slid the launcher onto the free floating rail system. Look closely at the HK53 flash hider and the buttstock and you might be able to tell what customer this demo gun was put together for. Also, the polymer mag in this rifle is one of the early prototypes that I remember seeing for the first time a couple of years ago.

When we moved on to the Gray Room Tour, I chose to focus my attention on the three early HKM4 variants. Clearly noticeable in the photos is how large the gas blocks were on these early guns.

Many of you, with MR556A1s and the few of you with HK416s, may ask what spare parts should I keep on hand? Well, of course I asked and the answer was the disconnector and it's retaining pin, firing pin and firing pin spring and the gas piston rings (as these wear, you'll begin to expereince underfunction in the form of failure to extract and eject). But before you rush out and stock up, I'll tell you that upon arriving back at work, I called over to our Armory to check with our Armory Chief on what parts have failed and needed replacement on our M27 IARs and he responeded with...wait for it...NOTHING. Sure that doesn't mean that you're never going to have a part fail, but it sure is impressive.

As for maintenance, the recommendation was FIRECLean and Scotch Bright 7447 for the gas piston. That combination has been very effective, especially when shooting suppressed.

And while I'm at it, here are a few other interesting items of discussion from our trip to Ashburn:

-The PSG1 has been officially discontinued/MSG1 still available

-France is replacing all of their FAMAS rifles and the HK416 will be entered in the program.

-VP9 Armorer Course coming soon!